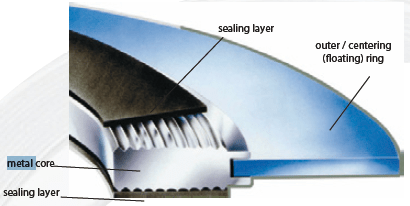

A Kammprofile gasket is manufactured by applying a sealing layer in non-metallic materials (such as graphite, PTFE-Teflon, ceramic fibers, non-asbestos, Mica, etc) or metallic materials (as aluminum or silver) on both sides of a metal core featuring concentric grooves of 1 mm Cam-Pitch. This sealing product, called also “grooved metal gasket” or “corrugated metal gasket”, is used for high-pressure and temperature oil & gas applications.

Kammprofile gaskets are used in many industrial, petrochemical, power generation and nuclear installations (to seal flanges, heat exchangers, superheaters and, other pressure equipment) and are preferred to Spiral Wound Gaskets for processes with constant high pressure/temperatures requiring strong bolt-loads and remarkable flanged joints’ resistance.

Kammprofile gaskets fit smooth and stock flange surface finish (3.2 to 6.3 μm Ra, i.e. 125-250 RMS).

The common thickness of a Kammprofile gasket is between 2 and 4 mm (3 mm is the most common specification in petrochemical applications).

A Kammprofile gasket offers several benefits, due to its wide sealing area and construction:

May resist temperatures up to approx. 1000°C (the Kammprofile temperature rating depends on the materials of the metal core and the sealing layer)

May rate up to 250 bars, which is a considerable pressure rating

The gasket does not damage the flange surface, due to the protection offered by the sealing layer

The gasket can absorb fluctuations in temperature and pressure

It is more tolerant than Spiral Wound Gaskets to improper bolting torques

Suits both light and heavyweight flanges, even of large sizes

After assembly, the thickness of the sealing material is extremely low (0.1 – 0.2 mm), thus reducing leaks and failure rates

The core of a Kammprofile gasket can be re-used after cleaning and fitting the gasket with a new layering material. This is critical for expensive applications, such as heat exchanger gaskets that are made of exotic, expensive, materials (Inconel, Monel, Hastelloy, and Cupronickel).

An outer metallic (integral or floating) ring may be added to the gasket, to facilitate the centering of the gasket during the installation on a flange. The sealing layers protect the flange surface and reinforce the seal.

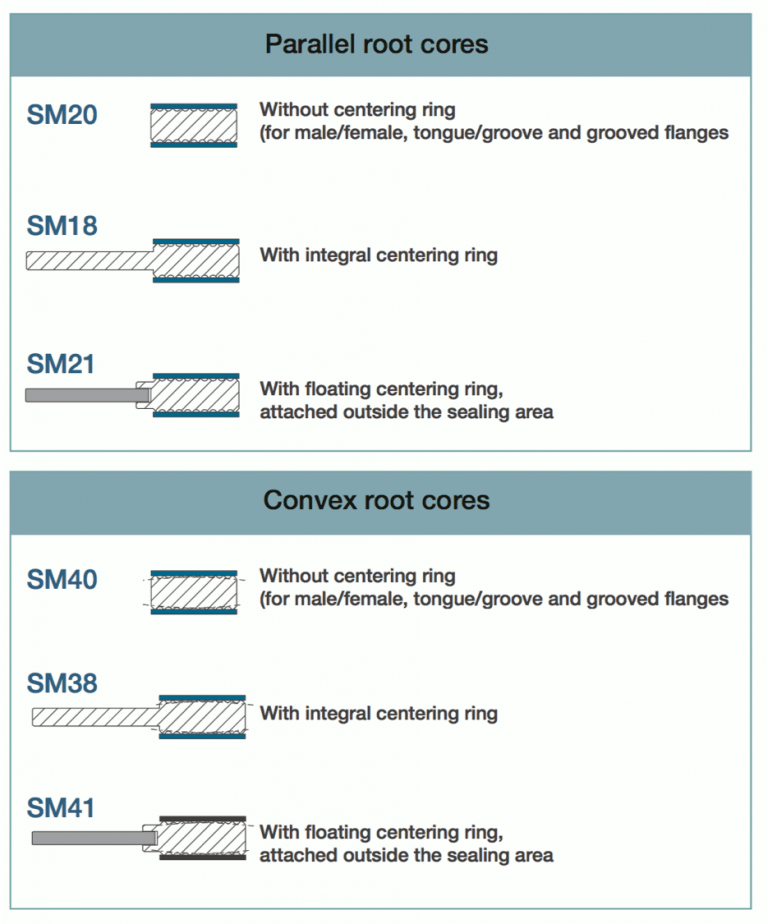

KAMMPROFILE GASKET TYPES

Kammprofile gaskets are available in two main configurations, parallel root cores/convex root cores, and two designs (with/without loose outer centering ring), as shown in the image below:

KAMMPROFILE GASKET MATERIALS

Metal Core Materials

The core material of a Kammprofile gasket shall match the material of the piping system

| Kammprofile Core Materials | DIN Designation | DIN Material Number | AISI ASTM UNS Designation | British Standard Designation | Hardness HB/HV | Temperature in C° Min. Max. | Density in gr/cm3 | |

| Soft Iron | – | – | – | – | 90 – 100 | – 60 | 500 | 7.85 |

| Steel (LCS) | RSt. 37.2 | 1.0038 | – | – | 100 – 130 | – 40 | 500 | 7.85 |

| Stainless Steel 304 | X5 CrNi 1810 | 1.4301 | 304 | 304S15/16/31 | 130 – 180 | -250 | 550 | 7.9 |

| Stainless Steel 304 L | X2CrNi 1911 | 1.4306 | 304L | 304S11 | 130 – 190 | -250 | 550 | 7.9 |

| Stainless Steel 309 | X15CrNiSi 2012 | 1.4828 | 309 | 309S24 | 130 – 190 | -100 | 1000 | 7.9 |

| Stainless Steel 316 L(1) | X2CrNiMo 1713 | 1.4404 | 316L | 316S11/13 | 130 – 190 | -100 | 550 | 7.9 |

| Stainless Steel 316 Ti | X6CrNiMoTi 1712 | 1.4571 | 316Ti | 320S31 | 130 – 190 | -100 | 550 | 7.8 |

| Stainless Steel 321 | X6CrNiTi 1810 | 1.4541 | 321 | 321S12/49/87 | 130 – 190 | -250 | 550 | 7.9 |

| Stainless Steel 347 | X6CrNiNb 1810 | 1.4550 | 347 | 347S31 | 130 – 190 | -250 | 550 | 7.9 |

| Aluminium | Al 99,5 | 3.0255 | – | – | 20 – 23 | -250 | 300 | 2.73 |

| Silver | – | – | – | – | 28* | -250 | 750 | 10.5 |

| Copper | – | 2.0090 | – | – | 50 – 80 | -250 | 400 | 8.9 |

| Nickel 200 | Ni 99,2 | 2.4066 | N02200 | 3072-76 NA11 | 90 – 120 | -250 | 600 | 8.9 |

| Monel 400 ® | NiCu 30 Fe | 2.4360 | N04400 | 3072-76 NA13 | 110 – 150 | -125 | 600 | 8.8 |

| Inconel 600 ® | NiCr 15 Fe | 2.4816 | N06600 | 3072-76 NA14 | 120 – 180 | -100 | 950 | 8.4 |

| Incoloy 800 ® | X10NiCrAITi 3220 | 1.4876 | N08800 | 3072-76 NA15 | 140 – 220 | -100 | 850 | 8.0 |

| Incoloy 825 ® | NiCr 21 Mo | 2.4858 | N08825 | 3072-76 NA16 | 120 – 180 | -100 | 450 | 8.14 |

| Hastelloy B2 ® | NiMo 28 | 2.4617 | N10665 | – | 170 – 230 | -200 | 450 | 9.2 |

| Hastelloy C276 ® | NiMo16Cr15W | 2.4819 | N10276 | – | 170 – 230 | -200 | 450 | 8.9 |

| Titanium | Ti 99,8 | 3.7025 | – | – | 110 – 140 | -250 | 350 | 4.5 |

Sealing Layer

The most common layer materials for Kammprofile gaskets are graphite and PTFE (Teflon).

The advantages of a graphite layering material are:

Excellent gas tightness qualities

Non-aging properties

Very good chemical resistance

Resistance to high (fluctuating) temperatures and pressures

PTFE is also used due to its excellent chemical resistance, resistance to temperatures up to 250°C and excellent sealing properties for gas applications.

| Sealing Layer Material for Kammprofile | Temperature in C° Min. Max. | Max. operating pressure in Bars | Gas tightness | Recommended Application | |

| Graphite | -200 | 550 | 250 | Good | Aggressive media |

| PTFE (Teflon ® ) | -200 | 250 | 100 | Good | Aggressive media |

| Non-asbestos | -100 | 250 | 100 | Good | Gas and liquids |

| Silver | -200 | 750 | 250 | Good | Aggressive media |

KAMMPROFILE GASKET DIMENSIONS

Class 150-400

Kammprofile gasket dimensions for AMSE B16.5 flanges

| NPS | d1 | d2 | d3 | ||

| 150 | 300 | 400 | |||

| 1/2 | 23 | 33.3 | 44.4 | 50.8 | 50.8 |

| 3/4 | 28.6 | 39.7 | 53.9 | 63.5 | 63.5 |

| 1 | 36.5 | 47.6 | 63.5 | 69.8 | 69.8 |

| 1¼ | 44.4 | 60.3 | 73 | 79.4 | 79.4 |

| 1½ | 52.4 | 69.8 | 82.5 | 92.1 | 92.1 |

| 2 | 69.8 | 88.9 | 101.6 | 108 | 108 |

| 2½ | 82.5 | 101.6 | 120.6 | 127 | 127 |

| 3 | 98.4 | 123.8 | 133.4 | 146.1 | 146.1 |

| 3½ | 111.1 | 136.5 | 158.8 | 161.9 | 158.7 |

| 4 | 123.8 | 154 | 171.5 | 177.8 | 174.6 |

| 5 | 150.8 | 182.6 | 193.7 | 212.7 | 209.5 |

| 6 | 177.8 | 212.7 | 219.1 | 247.7 | 244.5 |

| 8 | 228.6 | 266.7 | 276.2 | 304.8 | 301.6 |

| 10 | 282.6 | 320.7 | 336.5 | 358.8 | 355.6 |

| 12 | 339.7 | 377.8 | 406.4 | 419.1 | 415.9 |

| 14 | 371.5 | 409.6 | 447.7 | 482.6 | 479.4 |

| 16 | 422.3 | 466.7 | 511.2 | 536.6 | 533.4 |

| 18 | 479.4 | 530.2 | 546.1 | 593.7 | 590.5 |

| 20 | 530.2 | 581 | 603.2 | 650.9 | 644.5 |

| 24 | 631.8 | 682.6 | 714.4 | 771.5 | 765.2 |

| NPS | d1 | d2 | d3 | |||

| 600 | 900 | 1500 | 2500 | |||

| 1/2 | 23 | 33.3 | 50.8 | 60.3 | 60.3 | 66.7 |

| 3/4 | 28.6 | 39.7 | 63.5 | 66.7 | 66.7 | 73 |

| 1 | 36.5 | 47.6 | 69.8 | 76.2 | 76.2 | 82.5 |

| 1¼ | 44.4 | 60.3 | 79.4 | 85.7 | 85.7 | 101.6 |

| 1½ | 52.4 | 69.8 | 92.1 | 95.2 | 95.2 | 114.3 |

| 2 | 69.8 | 88.9 | 108 | 139.7 | 139.7 | 142.8 |

| 2½ | 82.5 | 101.6 | 127 | 161.9 | 161.9 | 165.1 |

| 3 | 98.4 | 123.8 | 146.1 | 165.1 | 171.5 | 193.7 |

| 3½ | 111.1 | 136.5 | 158.7 | … | … | … |

| 4 | 123.8 | 154 | 190.5 | 203.2 | 206.4 | 231.7 |

| 5 | 150.8 | 182.6 | 238.1 | 244.5 | 250.8 | 276.2 |

| 6 | 177.8 | 212.7 | 263.5 | 285.8 | 279.4 | 314.3 |

| 8 | 228.6 | 266.7 | 317.5 | 355.6 | 349.3 | 384.1 |

| 10 | 282.6 | 320.7 | 369.9 | 431.8 | 431.8 | 473 |

| 12 | 339.7 | 377.8 | 454 | 495.3 | 517.5 | 546.1 |

| 14 | 371.5 | 409.6 | 488.9 | 517.5 | 574.7 | … |

| 16 | 422.3 | 466.7 | 561.9 | 571.5 | 638.1 | … |

| 18 | 479.4 | 530.2 | 609.6 | 635 | 701.7 | … |

| 20 | 530.2 | 581 | 679.5 | 695.3 | 752.4 | … |

| 24 | 631.8 | 682.6 | 787.4 | 835 | 898.5 | … |

Behind Gasket India 'S growth and success there is years of experience working in steel industry & closely monitoring our customer's demands. Exclusive technology, certified products, high quality standards and perfect customer's services: this is Gasket India a true performer in the global market and a reliable partner for its customers.

Ratan Height A Wing, 14th floor, 1402, Gilder Lane, Opp Navjeevan Society, near Mumbai Central, 400008

gasketindia1@gmail.com

info@gasketindia.com

gasketonline1@gmail.com

+91 9930551137

+91 9082065807