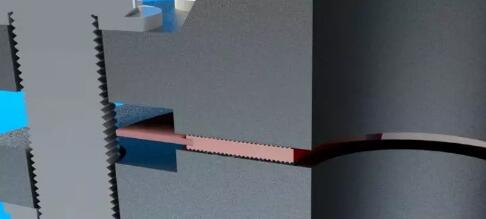

Metal serrated gaskets belong to a kind of metal composite gaskets. Generally, the zigzag grooves with 90 degree angle of concentricity are machined on the two sides of metal flat gaskets by precision lathe or special milling machine. Because the contact with other sealing surfaces is a linear contact of many concentric circles, they have labyrinth sealing effect. Flexible graphite can be selected according to different media and working conditions. PTFE, asbestos-free board or some other soft metals are pasted on the two sides of the gasket, making use of the sealing property of the soft covering layer and the strength and elasticity of the metal to achieve a better sealing effect. In most cases, we recommend graphite as the sealing layer. When the medium reacts to graphite or requires a clean environment, we recommend that we choose the newly introduced expander IV with excellent performance. Fluorine as adhesive layer, generally do not need a lot of pressure, can achieve sealing effect.

Metal serrated gaskets belong to a kind of metal composite gaskets. Generally, the zigzag grooves with 90 degree angle of concentricity are machined on the two sides of metal flat gaskets by precision lathe or special milling machine. Because the contact with other sealing surfaces is a linear contact of many concentric circles, they have labyrinth sealing effect. Flexible graphite can be selected according to different media and working conditions. PTFE, asbestos-free board or some other soft metals are pasted on the two sides of the gasket, making use of the sealing property of the soft covering layer and the strength and elasticity of the metal to achieve a better sealing effect. In most cases, we recommend graphite as the sealing layer. When the medium reacts to graphite or requires a clean environment, we recommend that we choose the newly introduced expander IV with excellent performance. Fluorine as adhesive layer, generally do not need a lot of pressure, can achieve sealing effect.

Serrated gaskets can also be directly used without covering sealing layer, and can achieve good sealing effect, but in high-pressure situations, flange surface is easily damaged. Therefore, the roughness of the sealing surface is generally required to be above Ra 1.6um.

Special working conditions such as extreme high temperature, strong corrosion, etc. require special material Metal serrated gaskets, we can also produce the following special materials can be required:

Stainless steel 304L, 321, 316TI, 309, 347, 410, duplex steel (2205, 31803), Monel MONEL (400), INCONEL (600, 625), INCOLOY (800, 825), HASTELLO (B2, C276), Titanium (T2) and other special stainless steel or alloy materials.

Performance characteristics of metal serrated gaskets:

Lower pre-tightening force, even in high pressure environment, has a good sealing effect, especially suitable for high temperature, high pressure, alternating working conditions of the occasion is an ideal substitute for traditional metal-wound gaskets and metal-clad gaskets.

Metal serrated gaskets do not damage the sealing surface and are easy to disassemble.

The metal tooth shape part can be reused, which is of great significance for larger gaskets or gaskets of special materials, such as heat exchanger gaskets.

Ret ring with concentric serrations made of various types of metal. Used when bolting force is not sufficient to seal a flat gasket, because it contacts flange face only at serration peaks. Commonly used on valve bannets and flanges attached to equipment. 3 types of cross section as per right table are available.

|

Type |

Cross Section |

|

Basic(A) |

|

|

With outer Ring(B) |

|

|

With inner and Outer ring(C) |

|

Width |

4.5mm |

3.0mm |

Cross Section |

|

Less than 10mm |

Inner diameter less than 200mm;0.75mm |

0.5mm |

|

|

10mm and above |

1.0mm |

Application Range of Metal Serrated Gaskets:

Tooth-shaped gaskets are mainly used in medium, high pressure and high temperature pressure vessels in petroleum, chemical, metallurgical, electric power, shipping, machinery and other industries, as well as in the sealing of heat exchangers, condensers and pipeline flanges.

History and Development of Metal Serrated Gaskets

Metal toothed composite gaskets are toothed composite gaskets with overburden. It was first developed and applied in Europe. Its toothed cross section was developed in Germany and was incorporated into the German pipe flange standard DIN2697 (DN10-400, PN 63, 100, 160, 250, 320, 400) about 40 years ago. Flange gaskets are widely used in heat exchangers and pressure vessels to replace metal-clad gaskets.

This gasket has been used in the high-pressure equipment of 480,000 tons/year urea plant (design pressure is 16.6 Mpa) designed by ourselves for a long time. At the end of the 20th century, it has also been used in many industrial plants in the United States to replace metal-wound gaskets and metal-clad gaskets. Over the years, the original design has been improved many times.

Sealing Principle of Metal Serrated Gasket

The soft material (flexible graphite or PTFE) covered on the two teeth surfaces of the metal tooth gasket not only fills the uneven defects on the contact surface of the flange easily, but also is pressed into many concentric circular grooves on the surface of the metal core. The compressive stress during the pre-tightening increases the density of the covering material (such as flexible graphite) in the groove and on the top of the teeth. Under the compressive stress of 200 Mpa, the density can be increased to about 2.27g/cm3.

When the average compressive stress of pre-tightening is very low, the compressive stress of flexible graphite at the top of the tooth will be very high, and it can still reach a high density. Thus, a multi-channel concentric high density seal ring is formed on the contact cross section between the flange and the gasket. Even if the cyclic variation of operating temperature, uneven thermal expansion and fluctuation of pressure lead to the change of bolt load and average compressive stress on gasket, graphite at the top of tooth can still maintain a high density state, and the springback of metal core can make gasket withstand the change of various loads and maintain a good sealing effect.

|

fundamental type |

Code name |

Applicable flange sealing surface |

Thickness (mm) |

|

|

Seal body |

Paste layer (single side) |

|||

|

Basic type |

YA-G410A |

Tenon groove surface, concavo convex surface, plane and groove face |

3, 4, 5 |

0.5-1.0 |

|

Outer ring (fixed) |

YA-G420C |

Plane or convex surface |

3, 4, 5 |

0.5-1.0 |

|

Outer ring (activity) |

YA-G421C |

Plane or convex surface |

3, 4, 5 |

0.5-1.0 |

|

Earring |

YA-G422C |

Plane or convex surface |

3, 4, 5 |

0.5-1.0 |

Main technical parameters of various non-metallic materials for serrated gaskets:

|

Material Science |

Identification code |

Temperature c |

Maximum working pressure |

Applicable medium |

Compression ratio% |

Rebound percentage |

Stress relaxation rate% |

|

expand graphite |

F.G. |

-220–550 |

250 BAR |

Corrosive medium |

|

More than 17 |

Less than 18 |

|

Teflon |

PTFE |

-100– 200 |

100 BAR |

Corrosive medium |

18–30 |

More than 15 |

Less than 13 |

|

Expanded polytetrafluoroethylene |

EPTFE |

-100–260 |

200 BAR |

Corrosive medium |

25–35 |

More than 25 |

Less than 13 |

|

Asbestos free material |

NA |

-100–350 |

100 BAR |

General tightness |

18–30 |

More than 19 |

Less than 28 |

|

mica |

MICA |

-150–800 |

100 BAR |

Extra high temperature |

18–30 |

More than 19 |

|

|

ceramic fiber |

CER |

-200–1090 |

100 BAR |

Ultrahigh temperature |

18–40 |

More than 19 |

|

The following table is used for material selection of metal skeleton of commonly used serrated gaskets.

|

Material name |

Abbreviation mark |

Hardness (HB) |

Limit temperature (C) |

|

Carbon steel (Carbon steel) |

CRS |

One hundred and twenty |

-40~+540 |

|

304 stainless steel |

Three hundred and four |

130~180 |

-195~+760 |

|

304L stainless steel |

304L |

130~180 |

-195~+760 |

|

316L stainless steel |

316L |

130~180 |

-100~+760 |

|

317L stainless steel |

317L |

|

-100~+760 |

|

321 stainless steel |

Three hundred and twenty-one |

130~190 |

-195~+760 |

|

347 stainless steel |

Three hundred and twenty-one |

|

-185~+760 |

|

20CB-3 (ALLOY 20) |

A-20 |

|

-185~+1090 |

|

HASTELLOY-B2 |

HAST B |

Two hundred and fifteen |

-185~+1090 |

|

HASTELLOY-C276 |

HAST C |

|

-185~+1090 |

|

INCOLOY-800 |

IN 800 |

|

-100~+870 |

|

INCOLOY-825 |

IN 825 |

|

-100~+870 |

|

INCONEL-600 |

INC 600 |

One hundred and fifty |

-100~+1090 |

|

INCONEL-625 |

INC 625 |

|

-100~+1090 |

|

INCONEL-X750 |

INX |

|

-100~+1090 |

|

MONEL-400 |

MON |

One hundred and fifty |

-130~+820 |

|

NICKEL-200 (nickel) |

NI |

|

-195~+760 |

|

TITANIUM (titanium) |

TI |

Two hundred and fifteen |

-195~+1090 |

Dimensional limit deviation of serrated gaskets:

|

Internal diameter of toothed seal D1 |

The outer diameter of the toothed seal is D2 |

Outer ring outer diameter D3 |

Thickness T |

|

+1.5 |

Zero |

+1.5 |

+0.25 |

The main parts of the serrated gaskets are performance parameter :

|

Gasket coefficient |

M=4.25 |

|

Use of gaskets pressure |

Less than 25MPa |

|

Service temperature of gaskets |

-196 C -650 C (no more than 450 C in oxidizing medium) |

|

Minimum preload specific pressure of gasket |

Y=50MPa |

Behind Gasket India 'S growth and success there is years of experience working in steel industry & closely monitoring our customer's demands. Exclusive technology, certified products, high quality standards and perfect customer's services: this is Gasket India a true performer in the global market and a reliable partner for its customers.

Ratan Height A Wing, 14th floor, 1402, Gilder Lane, Opp Navjeevan Society, near Mumbai Central, 400008

gasketindia1@gmail.com

info@gasketindia.com

gasketonline1@gmail.com

+91 9930551137

+91 9082065807